In 1972 ben ik met een oude Agfa camera begonnen met fotograferen. Daarna is het allemaal uitgebreid met het afdrukken van foto’s en dia’s en de overstap naar digitale fotografie heb ik in 2005 gemaakt. Met daarna alle mogelijke updates en -upgrades.

Uiteindelijk maakt het niet uit waarmee je foto’s maakt, maar wat je vastlegt. En- toen dat steeds beter werd ben ik ook overgestapt van analoge video naar digitaal opnemen.

Naast het vastleggen van mooie plaatjes met en zonder beweging vind ik het leuk om met verschillende camera types te werken. Zo heb ik onder andere een Lytro Yllum voor dieptefotografie en maak ik graag gebruik van de MFT-lijn van Olympus en de semi-pro bijbehorende lenzen.

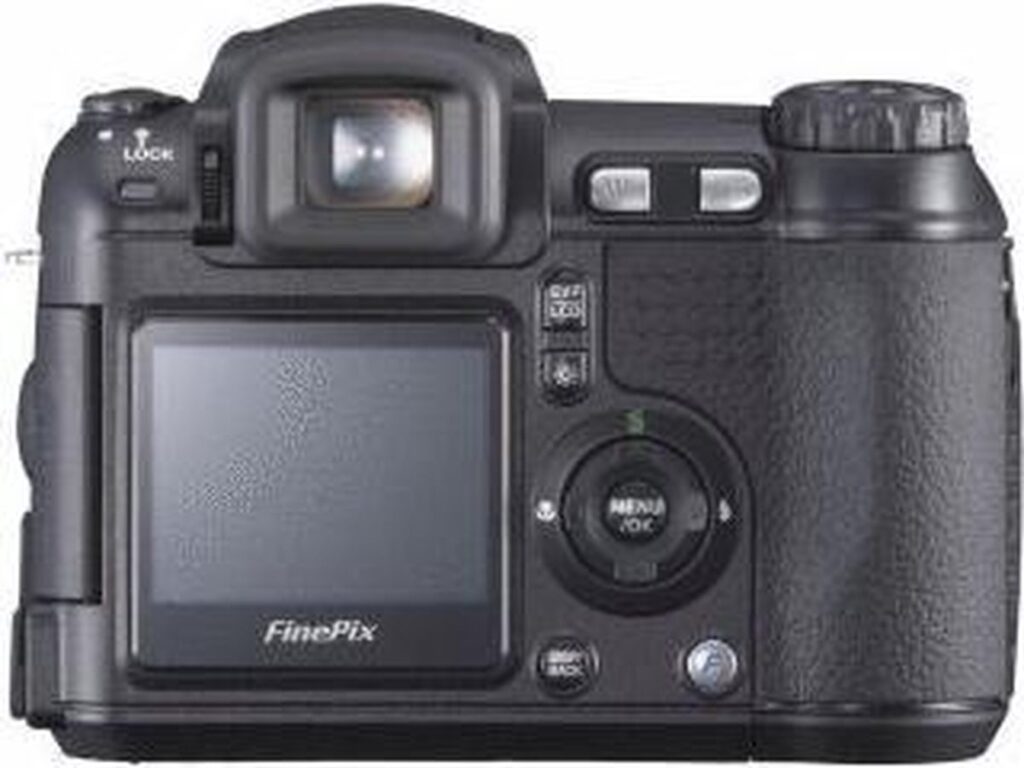

De afgelopen jaren heb ik vanaf mijn eerste echte digitale camera, een Fujifilm finepix S5600 uit 2005 bijgehouden wat er allemaal te koop was en daarvan ook steeds gekocht en gebruikt wat naar mijn idee voor mij een goede keus was.

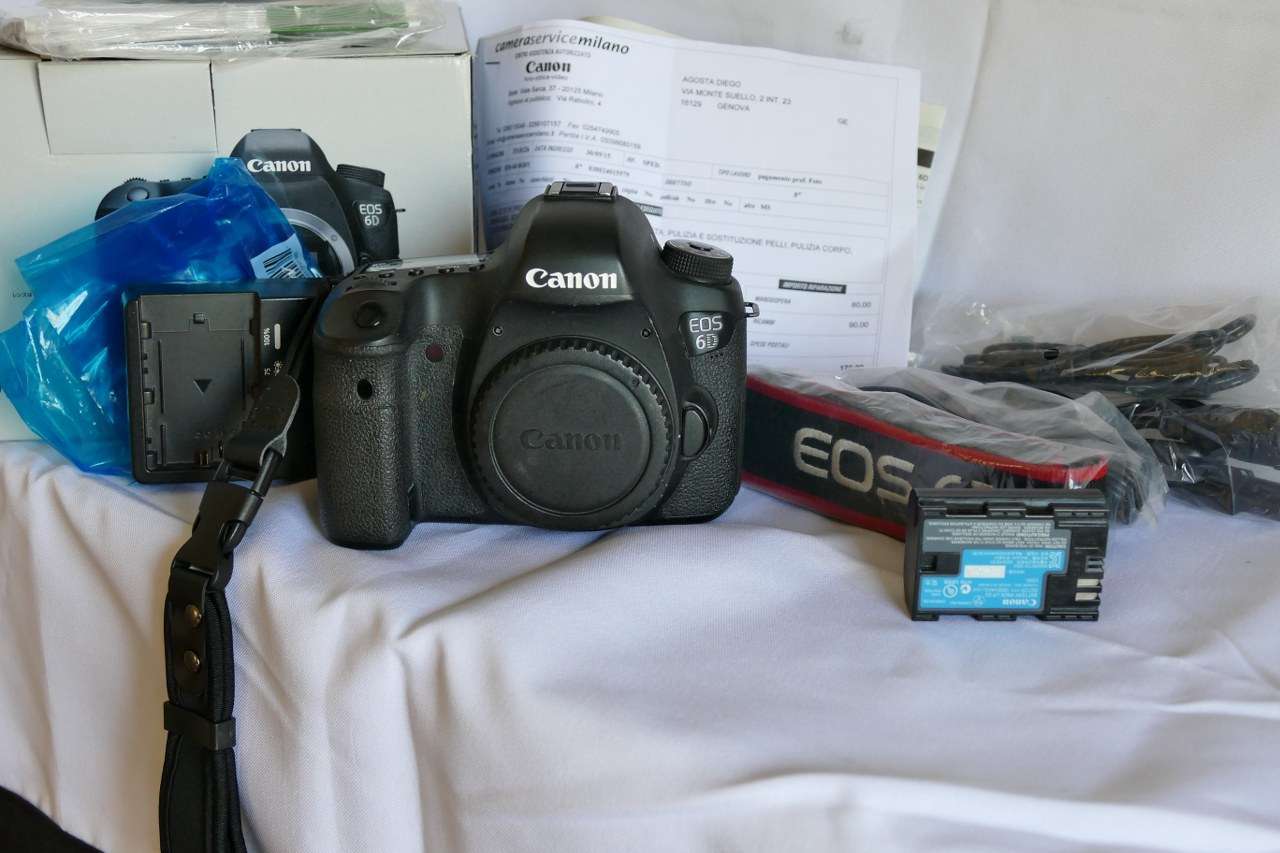

Zo ben ik de merken ook langs gegaan en ben ik eerst gestart met Canon, de EOS5DII en later de EOS6D en een aantal APS-C types. Daar heb ik ook zo’n beetje alle lenzen voor, van groothoek-zoom tot aan tele-zoom en een behoorlijk aantal primes. Van Canon heb ik ook een paar camera’s uit de M-serie inclusief dubbele set lenzen maar daar gebruik ik eigenlijk niets van omdat de kwaliteit prima is maar onvergelijkbaar met mijn full-frame en M4/3 apparatuur. Terwijl de mogelijkheden van de M serie minder zijn dan van merken als Panasonic, Sony en Olympus en de portabiliteit is ongeveer vergelijkbaar.

Omdat ik ook graag film ben ik op een gegeven moment naast de Canon full-frame camera’s die ik voor still fotografie nog steeds gebruik overgestapt naar de Sony A7 lijn. Daarvan heb ik mijn eerste A7 nog, maar ook de multipixel A7RII. Ook voor deze camera’s heb ik een redelijke set lenzen, maar toch vooral zoomlenzen vanwege de primaire inzet van deze camera’s als filmcamera. Ik vind (en dat is natuurlijk heel persoonlijk) de look en feel van Canon heel goed passen bij snel even een foto maken en de Sony Camera’s zijn me daar te hoekig voor. Prima in een frame met allerlei extra’s er aan maar niet als camera voor walk-arounds.

Uiteindelijk ben ik zo rond 2018 verslingerd geraakt aan de Olympus- en Panasonic– lijnen met de micro 4/3 sensors. Ik heb daar de top camera’s zo’n beetje van in mijn bezit, en daarbij ook een groot aantal lenzen. De 2 camera’s die ik het meest gebruik zijn de Olympus OMD-1 MII en mijn favoriete walkaround is de Panasonic DC-G90 met de korte OLYMPUS MFT 7-14MM F/2.8 M.ZUIKO erop.

Op vakanties gebruik ik nooit meer iets anders dan mijn Sony RX-100 MV. Met het uittrekbare oculair en de bijna onverslaanbare beeldkwaliteit van de 1 inch sensor heb ik ervaren dat ik nooit meer iets anders hoef mee te nemen voor onderweg. On top of all maakt deze camera ook hele goede video-opnames.

In de stad pak ik meestal mijn Canon RP met de korte zoom F4.0 14-35 er op.

Lekker compact en ongecompliceerd.

Voor reportages gebruik ik graag mijn setje Panasonic GX8‘s. Kan een stootje hebben, is inclusief flits en door het aanwezige verstelbaar oculair (zoeker) altijd goed bruikbaar, ook bij fel zonlicht. op deze camera’s heb ik meestal de Panasonic- korte zoomlens en een Olympus prime gemonteerd.

Bovenstaande opsomming betekent wel dat ik zo’n 80-90% van mijn fotospullen nooit gebruik. Ik heb geprobeerd alles te verkopen maar het levert me gewoon veel te weinig op. Dus pak ik af en toe een setje uit de kast en gebruik het weer eens een keer, dat is ook wel heel leuk!

Maar ik merk dat ik daarnaast steeds meer gebruik maak van mijn telefoon waarop een hele goeie camera zit, vooral voor video opnames. Op deze site vind je een indruk van mijn verzameld beeldmateriaal. Cheers, Jan

[Best_Wordpress_Gallery id=”56″ gal_title=”Cameras”]