For what it’s worth, the articles I write are not only based on my opinion and experience, common sense is also part of my written content.

In the first place you should ask ourself what you would define to be a professional 3d printer. Is it about price, durability, quality, size, usability, repeatability, speed, portability, cloud-based usage, shared usage, or possibly some other requirement that you find inportant? If you read the world’s professional literature about 3d-printing, it is always about either making one-off products or prototypes for complex (machine, dental, medical) purposes, or it has to do with printing parts in series for a specific branch of industry. In both cases, the to be printed material is mostly nothing like the hobbyist uses. Professional printing goes from carbon/fiber to stainless steel, ceramics, titanium and so on. Most professional production printers are in the price range above 30 k Euro.

3d printers from 500 Euro up until 15 k Euro are usually very good and precise at printing with common materials like ABS/PLA/Nylon/PetG, Carbon/wood et cetera and have a higher price tag than standard consumer models due to specific added value like the ability to print really big models, heated chamber, multicolor et cetera.

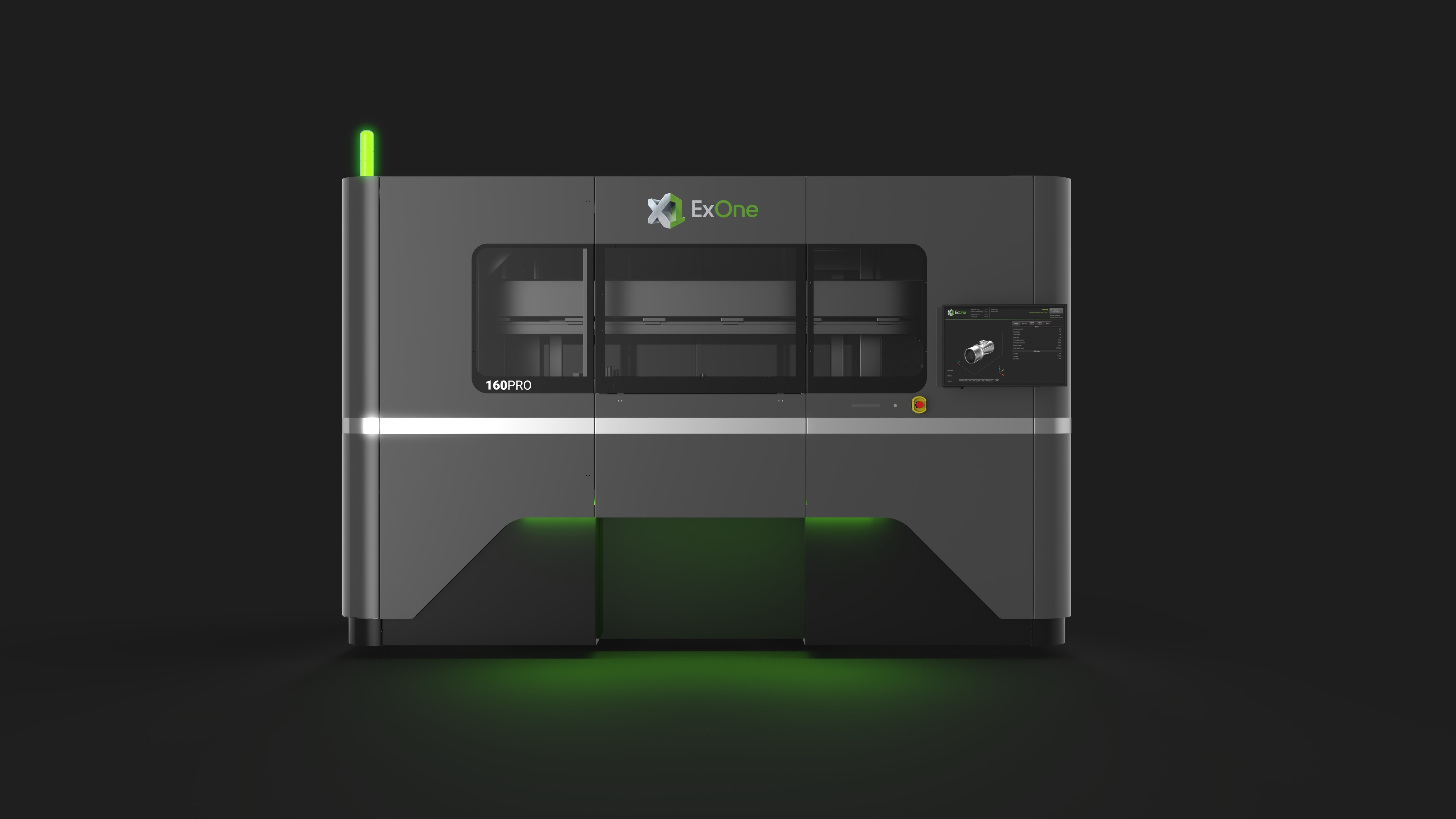

The X1 160Pro™ is the world’s largest metal binder jetting system and is now shipping to customers. A controlled-atmosphere model of the system, capable of high-volume aluminum and titanium production, will be available in late 2022. (Photo: Business Wire)And- after printing, most of these printed parts need post-processing like sintering for aluminium.

The price for professional 3d printers is a summation of a number of drivers, like:

- Developing / staffing

- Developing / materials, software and so on

- Tools, offices, warehouse and so on

- Patents costs

- Price and quality of materials

- Production costs

- Marketing costs

- Post-delivery costs (Service/maintenance)

With the hobbyist’s 3d printers, there is really only one driver for the costs, which is materials and production. Of course the quality is an issue here because cheap parts of lesser quality will make products of lesser quality. All other drivers from the above list are not required and/or have already been put in the public domain and are therefore not put in the final selling price. With professional 3d printers, the production numbers are usually low, quality high and developing processes are usually lengthy and expensive. Thus, the price per sold 3d printer will be uplifted a lot from the development related costs. On top of this, the real development of 3d printing is not even starting. The pioneers that develop printers will have to keep developing over and over again. Only when professional 3d printers will be in a stable production phase and development is more like tweaking than making large steps, it is possible to see prices drop.

So- to answer the question: No, professional 3d printers are not overpriced. But- they are expensive and are only interesting if you already need products that can be made today with such a specific printer. Think of car parts development, Formula 1- engine developments and so on. In these industries, it is very expensive to get a mold and rework a rough newly developed product in the conventional way so a 3d metalprinter will fulfill an already existing need. And the investment will pay back very quick due to the fast production times. And- the engineers that design a part can just use their existing tooling to make designs for 3d printing.