Recently (9-2021) I was able to buy me a tailgate and wheel cover from a wheeled TA version. This was the start of my project to convert my 1955 Citroën Traction Avant into a wheeled version.

It’s a matter of taste of course, and I just think a wheeled version is much nicer than such an imposed trunk.

Below you can see what my car would look like with a wheel instead of a trunk:

And, for comparison what my car looks like BEFORE the conversion to wheel:

Picture dates from 2007

Picture dates from 2007

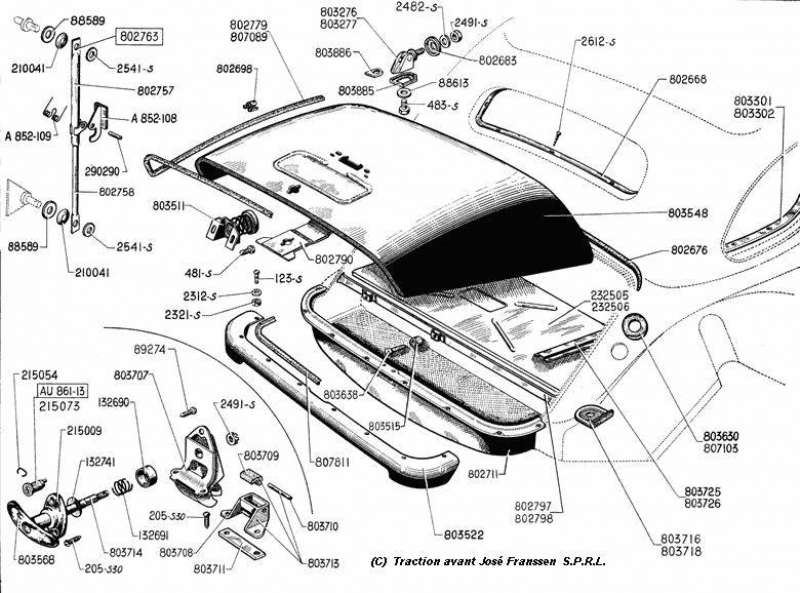

The trunk hangs from the part of the body directly under the rear window.

On a wheel version, there is still a section of sheet metal under the “kink” in the sheet metal that is under the window. That is completely missing from the trunk model.

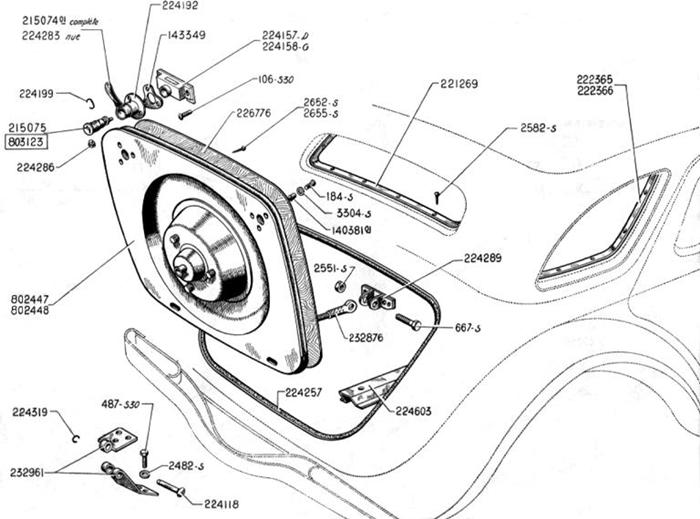

And the underside in terms of sheet metal runs all the way through (gray) , including under the trunk lid (gray lid with black wheel cover). This should be constructed anyway, and connected to the existing trunk floor plate. Everything under and behind it has to be removed so also the spare wheel well and the existing extra extension of bumper brackets and the ‘standard’ extra bolted-on sheet metal.

The fender points L and R are connected with a piece of sheet metal, under the fixed body (grey). This sheet metal part is still readily available as an aftermarket part.

THE APPROACH – is planned for mid 2022, after finishing the ID20 –

LPG tank out, gasoline tank out from under it.

OUTSIDE THE CAR:

First, a fender edge is made that follows the exact shape of the trunk lid of the wheeled version. Then a sheet metal edge is made that fits in the hole created when removing the existing boot lid. After that, it’s going to be a lot of fitting and measuring. Temporarily the new sheet metal part with sheet metal edge for the lid is fixed with U-strips instead of the lid. This makes everything a lot easier to handle.

ON THE CAR:

Next, the new sheet metal part is fixed in place and secured with small MIG dots.

Then mark where the excess material needs to be removed.

Grinding off the new sheet metal, and

everything to size, strip the edges and reposition the new part

Welding the new part in place, measurements and dots.

Weld in the 2nd round of dots.

Then fit the valve.

Mount the valve and fix it (by MIG welding the dots to the edge of the plate).

Then weld the plate to the body with a few spots at a time, and keep cooling with air.

Weld in further and further until everything is welded in, and wait and cool with compressed air.

Then without heating grind flat with flapper wheel and

Then use fiber 2-K waterproof filler to seal the weld and immediate area.

Then bondo over the whole, and

flush with 60 grid.

Filler primer over it,

spray contrast on,

manually level with 200,

then spray again contracts

and flatten with 400 etc.

Remove pinholes and again after

Contrast spray and sand with 800.

Waterproof sanding with 1200 and

then to the painter.

CAUTION to use light gray filler, bondo etc. of the same hue/color, this will save possible misery afterwards when spraying.