While I was making my CNC adapter plates with teethed wheels and belts, I discovered that not much exists that is ready to use for these conversions.

I am therefore also making direct drive adapter parts, to try this out.

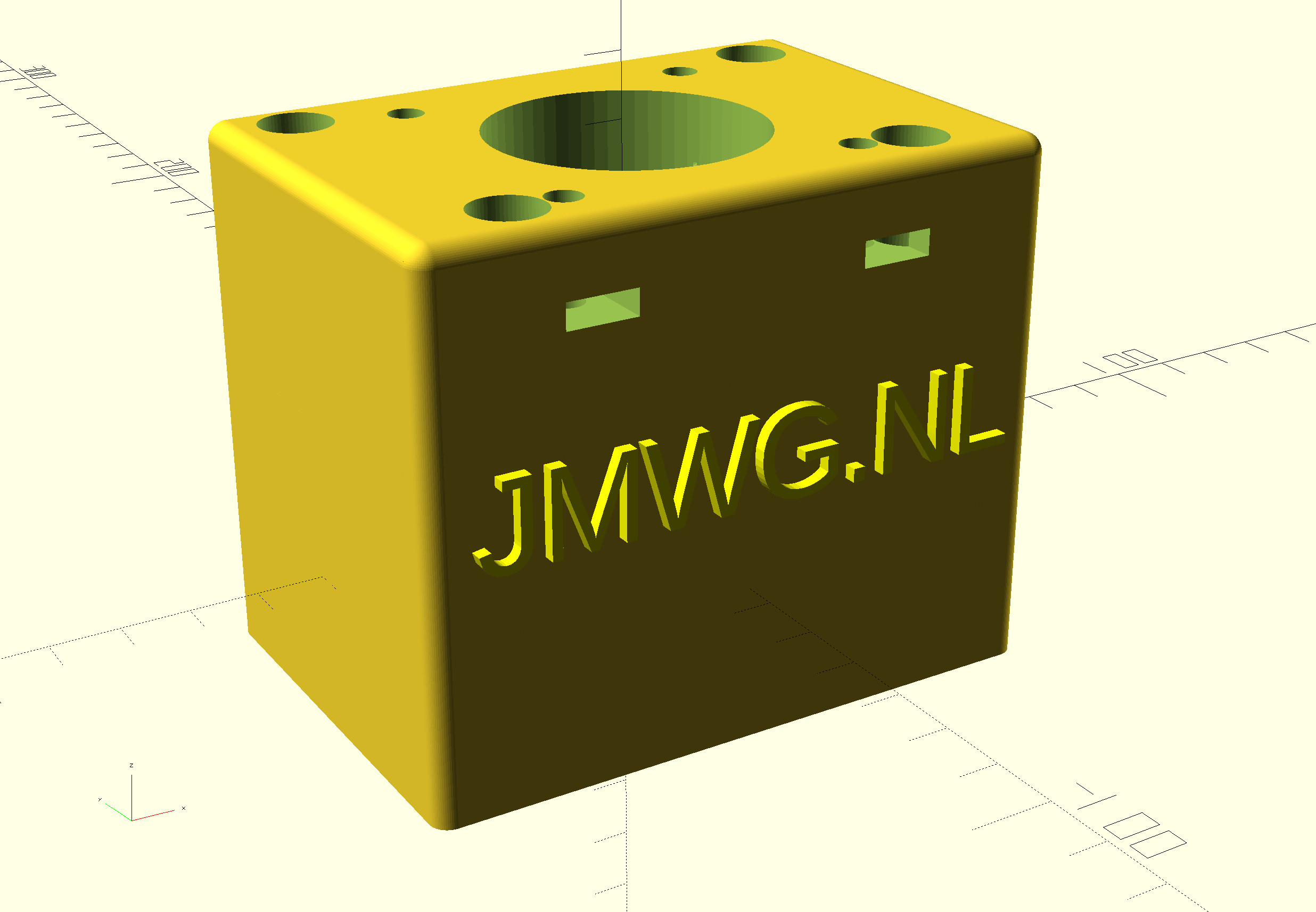

This is the third piece I make for direct drive, for the Z-axis.

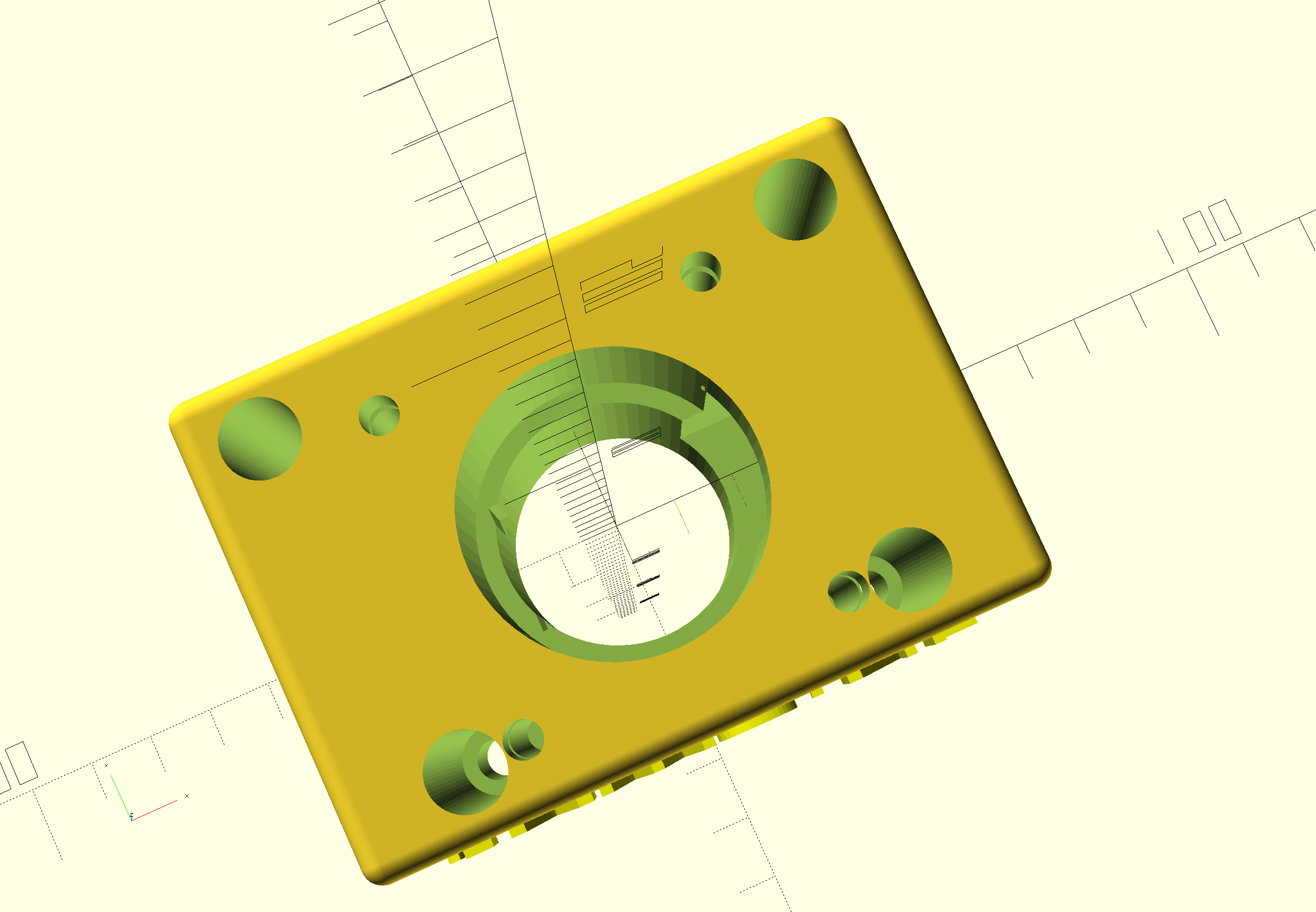

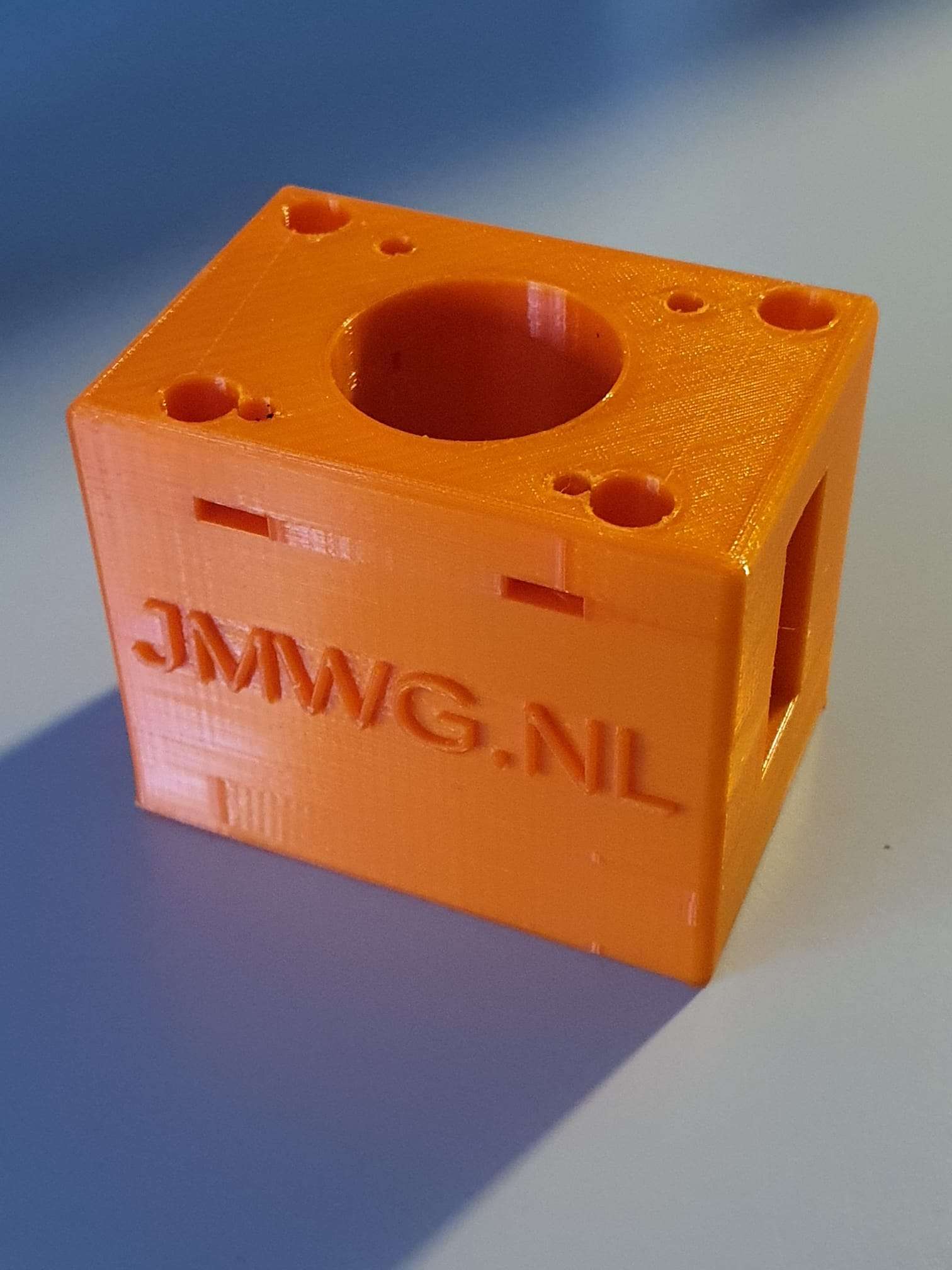

This pice is fairly simple: First a good fit is needed to mount the adapter to the top of the Z-column, and the holes for the 4 bolts need to be acactly correct. Also, the same for the leadscrew hole of the bearing holder.

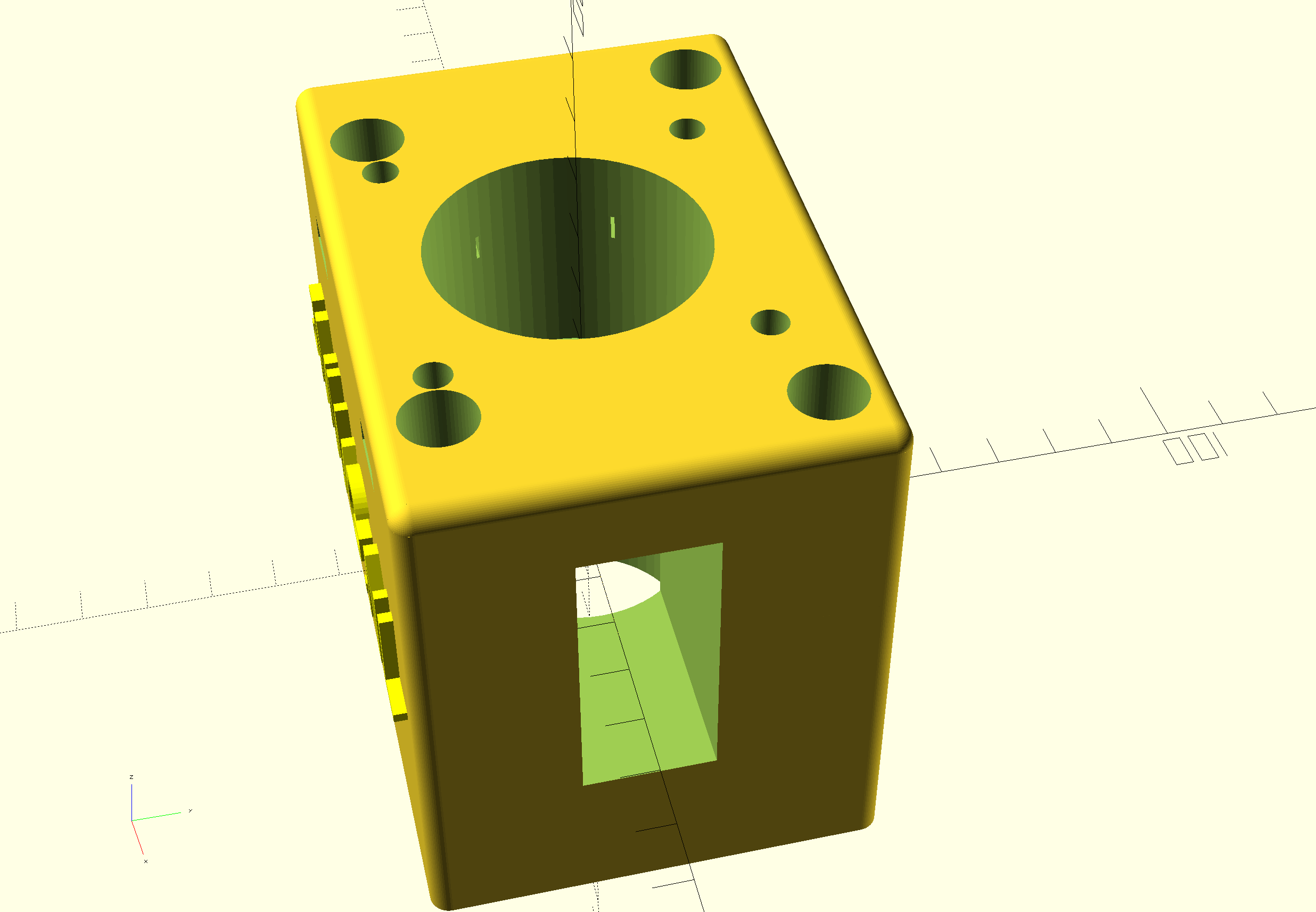

Then, on top of this, the Nema23 holder/mounting is projected. Including all needed boltholes, nutholes and a side hole for tightening the coupler.

The leadscrew has an outside part for the handwheel we will use for CNC that is 10mm, and some thread 10mm for Z. The thread is needed to be bolting the angular bearings (not meant for side torque) with some torque to the bearing holder.

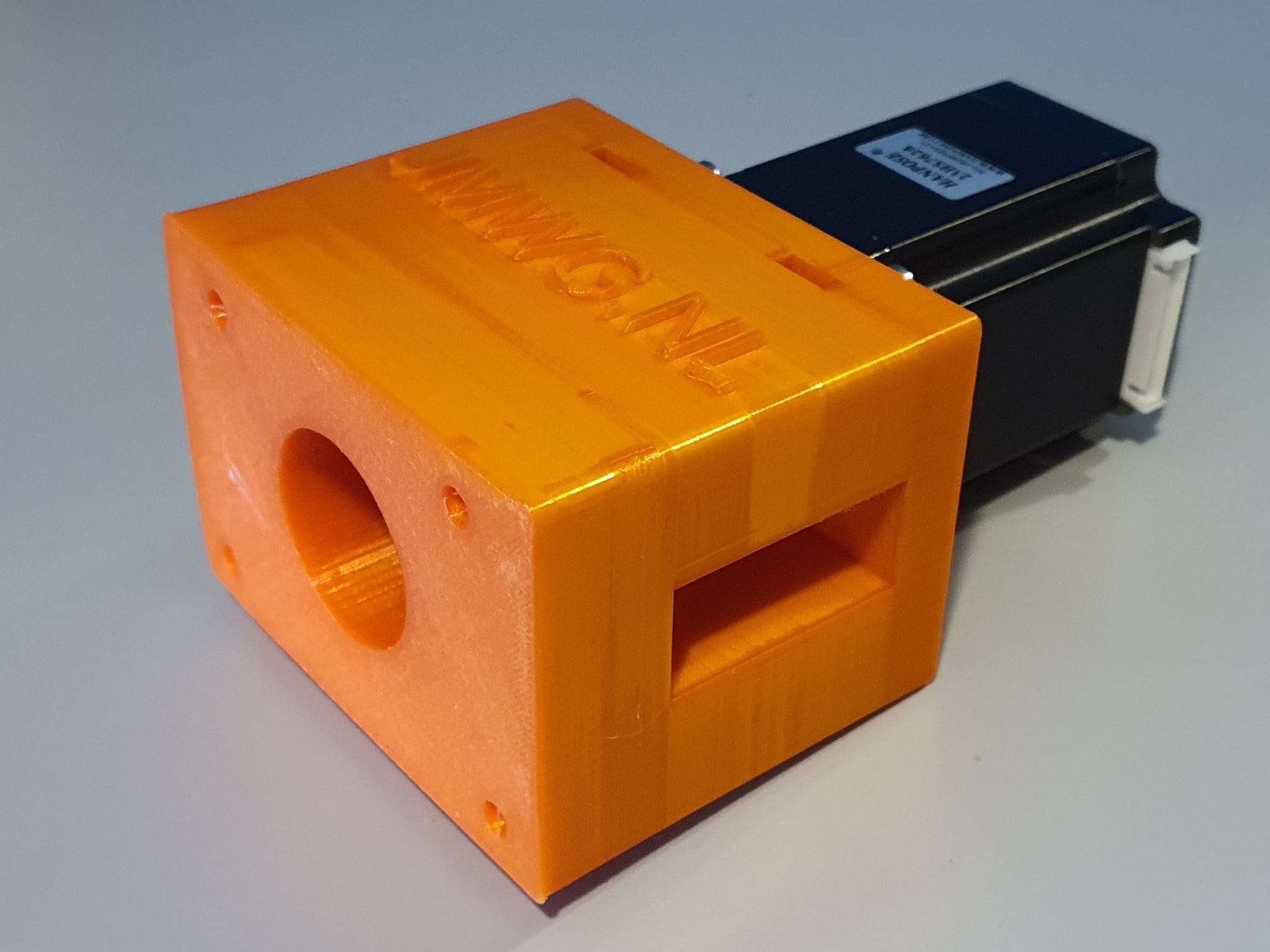

If you do direct drive, you need a special coupler that can be split in 2. Then, you first mount one part on the leadscrew with some rings between the mill and the coupler part so that the nut can be placed in the coupler. If the thread is too long, grind some off.

Then, put the rubber (with centerhole) back in the coupler’s mounted part and push the other part in the rubber, so the coupler is complete.

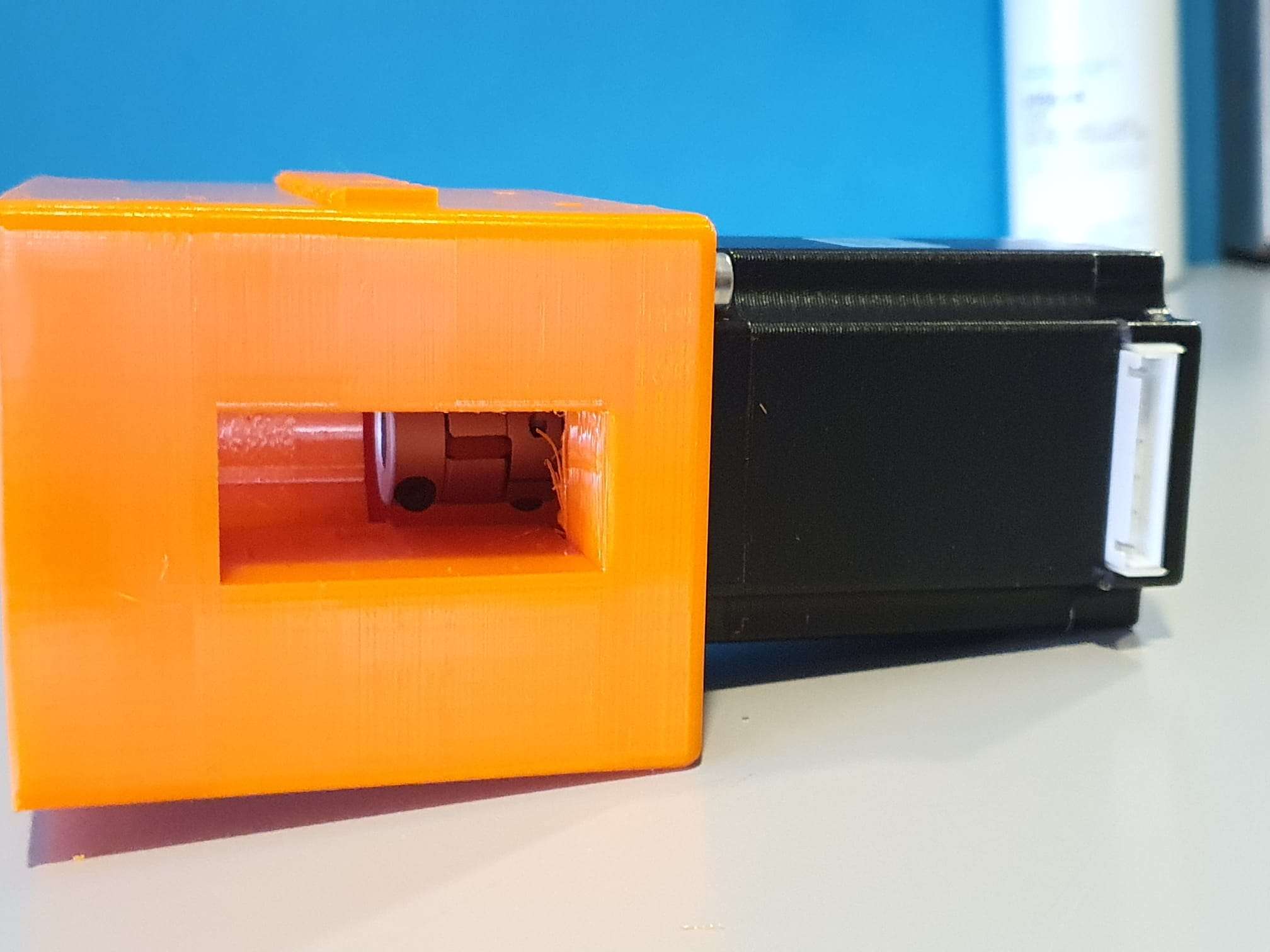

Then, mount the printed adapter with already mounted Nema23 motor on the Y-axis and push the Nema shaft in the coupler. Use the adapter’s right hand side working window to torque the connector on the Nema shaft and you’re done!

Should you want to have a handwheel as well, this is possible but you will have to buy a stepper with an axis that is both at the front as the rear. (this is called ‘double shaft’ but is actually a longer shaft, obviously.]

GOTO the X-axis Direct Drive adapter

GOTO the Y-axis Direct Drive adapter

DOWNLOAD LATEST VERSION OF THIS PART IN MY SHOP

BUY THIS PART IN MY SHOP will come soon