Started today September 1, 2021 the complete makeover of the Citroën ID20 originally converted to convertible by Oord in 2016.

This was the car at the (pre-) last round of paint (primer) in 2018:

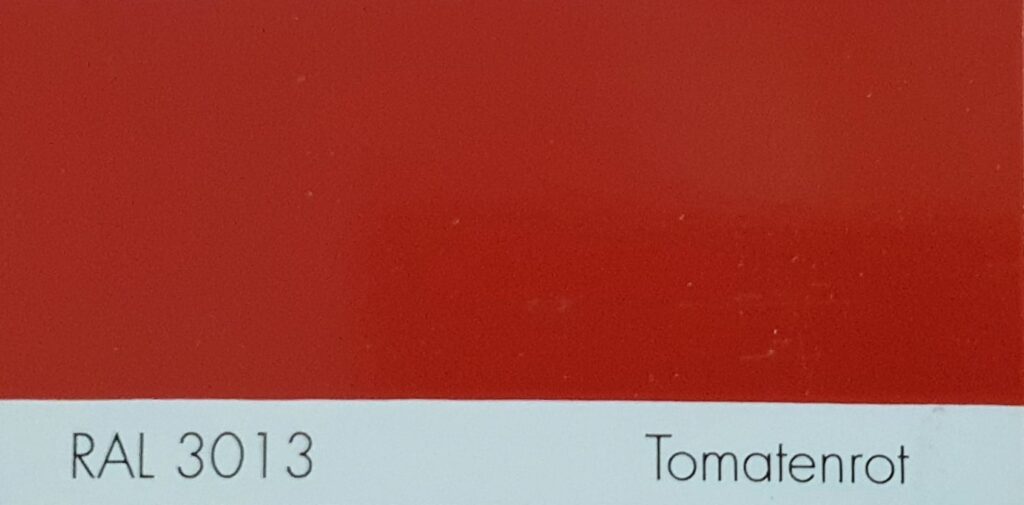

And- this time the color will be RED:

The exterior of the car will be completely dismantled, all sheet metal will be removed and where necessary, made tidy.

The original stainless steel Pallas wheel covers will be replaced, the plastic (2CV) spoke covers will be removed.

The front bumper has been disassembled and is being polished. The rear bumper will be replaced for a newly purchased extended convertible bumper, also already completely polished.

The roof will be completely recalibrated and the cover plate of the roof will be covered with Sonneland fabric. The black Sonneland cover is fitted with the typical push buttons.

The original 1966 Citroën ID tilt front seats go to the upholsterer and new black leather is fitted.

All loose parts are removed from the car, then the car is tightened. First coarse sanding, 2k primer, contrast spraying, medium sanding, fine sanding and then to the painter.

Oh yes, the air conditioning will be removed. That is very superfluous on a convertible and I can also remove the extra radiator of the airco that sits in front of the cooling water radiator. That saves on originality!

And that ugly antenna goes off at the same time! I have a reinforced antenna that goes on the inside of the windshield. On the right side. That is hardly visible and very easy to hide in terms of cabling, and close to the radio! And this antenna can be used for DAB+ at the same time.

The car will be tomato red RAL 2013. The professional (Basf) Glasurit 2K paint, hardener and thinner is already in stock! The inside, side, bottom and top of all sheet metal parts will also be painted red. The inside of the trunk, doors and doorposts will be red as well.

After painting, finally the by then re-upholstered seats can be put in and all new grey NOS carpet parts can be mounted.

The trunk lining can then be put in as well, and then all the external parts that were previously removed and either refurbished or replaced can be fitted.

Specifications: 4-cylinder in-line ID20 with 2.3 liter engine, two-stage carburetor and original electronic ignition. Air conditioning (manual). Manual sunroof. 4-person, 2-door version. LPG installation on the license plate. Last 2 years renewed: Water pump, alternator, hydraulic pump and fuel pump (All precautionary).

The intention is to put the car up for sale in the spring of 2022, to make room for a next project.

A P1800S with 1970-1973 build and overdrive would be a nice idea.

Or building a mehari yourself with one of those French replica mehari kits, or maybe stripping a 2CV and then using a fresh chassis and the old 2CV stuff to build the body of a Mehari.

Well, as long as petrol cars are still allowed to drive around, I can continue with the hobby for a while….

Update September 3, 2021: Completely emptied the front fenders, and removed all the tar and tectyl. Ordered a new replacement plate (left mounting eye was a bit baked on, will be made neat again with a new eye and replacement plate in the inner fender. . Fender edge will also be repaired).

The headlight housings will be cream colored again, they are black now. There are already new headlight mirrors in them so that saves some time.

The front wings were completely cleaned on the inside and underneath and then put in grey hammerite.

On the wheel arch side, there will be a black colored protective polyester coating. in my experience, that is the only way to protect the inside in our wet country with all kinds of gravel and other debris on the road.

In the rear, I previously installed aftermarket aluminum mud trays for protection in the inner fenders.

I completely disassembled the front bumper and replacement (very good NOS) sheet metal parts were arranged. The air horns were bad and the rest of the bumper connecting sheet metal was pretty bad too.

The license plate holder is also immediately replaced for a NOS one. The bottom of the licence plate holder has also become a bit too thin.

I had replaced the stone trap for a polyester type much earlier, so that will come off but it will also go back on after the underside has been cleaned, painted in the right color (same as the body) and the plating on the bottom has received a black anti-corrosion treatment.

The engine and gearbox, drive shafts, suspension and wheel bearings will be overhauled this winter, so these will also be taken out completely so that I can access the chassis properly.

I have to check if the threaded bushings in the chassis where the double front suspension is mounted are still in place. 14 years ago one bushing on the right side was welded again, but only on the outside because the engine was still there. Now that everything is going to be taken out anyway, I can do the inspection on this point at the same time.

After the front wings, it is time for the doors. I am going to saw off the bottom so that the normal size of an original convertible door in terms of height remains. Then I’m going to weld the doors shut and finish them off. The body near the doors will be widened to the outside of the door so that a wider sill becomes visible on the outside below the doors. In this way the bodywork under the doors continues from the front near the A-pillar to the rear. The yet to be purchased lower decorative strips then run from the A-pillar to the rear reflector in one go.

Lengthening the doors is not an issue, because the first Chapron models were also executed with the original size of the front doors. Nice excuse not to do that with my convertible either. In terms of boarding, there is not much improvement. With the new old handle seats, the backrests can easily be moved forward, if anyone would want to ride in the back. Besides, it is far too much work to have all the windows made anew, moving the B-pillar I see as possible but also a shame to open everything again now that everything fits nicely.

THE SPUITWORK

Because painting is a profession, I’ve been looking for a paint booth that can be rented near the garage and the workshop of the ID20 convertible. But it turns out to be difficult just to rent a space for half a day. Since I do all the prep work myself and already have the paint and such in stock, there is little to be gained for the rental company. I also take my own sprayers with me. And, if necessary, also the compressor and dehumidifier.

So it will probably come down to me spraying the car in my own garage. In preparation, I have already made the suction in the existing recesses in the outer wall, and the filter can easily be placed against that. Heating comes from 3 electric radiant heaters that can be attached to the ceiling, of the type outdoor heater.

The suction of the compressor comes from under the greenhouse, which is completely covered. In the pressure line there is a dehumidifier, in the spray room the dehumidifier is on continuously before spraying and I spray HVLP with about 2 Bar.

Lighting from the ceiling is arranged with 8 fixed LED fixtures, from the side also 8 LED x 120cm LED fixtures are placed, with cold white light 6800K.

Before spraying with the Glasurit 2K lacquer, I cover both the ceiling and walls and floor with plastic so that dust has no chance. The extraction and suction of air goes through filter boxes. I get my own air for inhalation from outside through a long 34 mm hose. During spraying, all doors are unlocked and there is always someone around. The compressor is outside the spray room so the overpressure must be able to get outside through the filter box and the fans in the wall. I don’t expect much spray with the low spray pressure and the electrostatic preload on the car. So also in terms of breathing I don’t think I’ll have any problems but as a precaution I prefer to get my own air clean from outside.

The garage is 3.5 by 5.5 meters and now that all the stuff from the garage is in the greenhouse, I can easily walk around the ID20. So the spraying should also be easy. I plan on when spraying it to do the inside of all things like doors, screens, tailgate etc first and then the outside. Since I disassemble all rubbers BEFORE spraying, I can just close the doors and lid after spraying the inside and continue spraying in one pass.

First layer with 5-10% thinner and the second layer after 15 minutes just pure. The third layer goes after 30 minutes with 5% thinner and the last layer after 45 minutes with 10% thinner.

This (already 12 years old) Glasurit paint does NOT need clear coat to get a good shine and because of the thickness of the paintjob I can always clean/polish the car for an even better finish!