I bought a couple of BIQU H2 extruders to experiment with them.

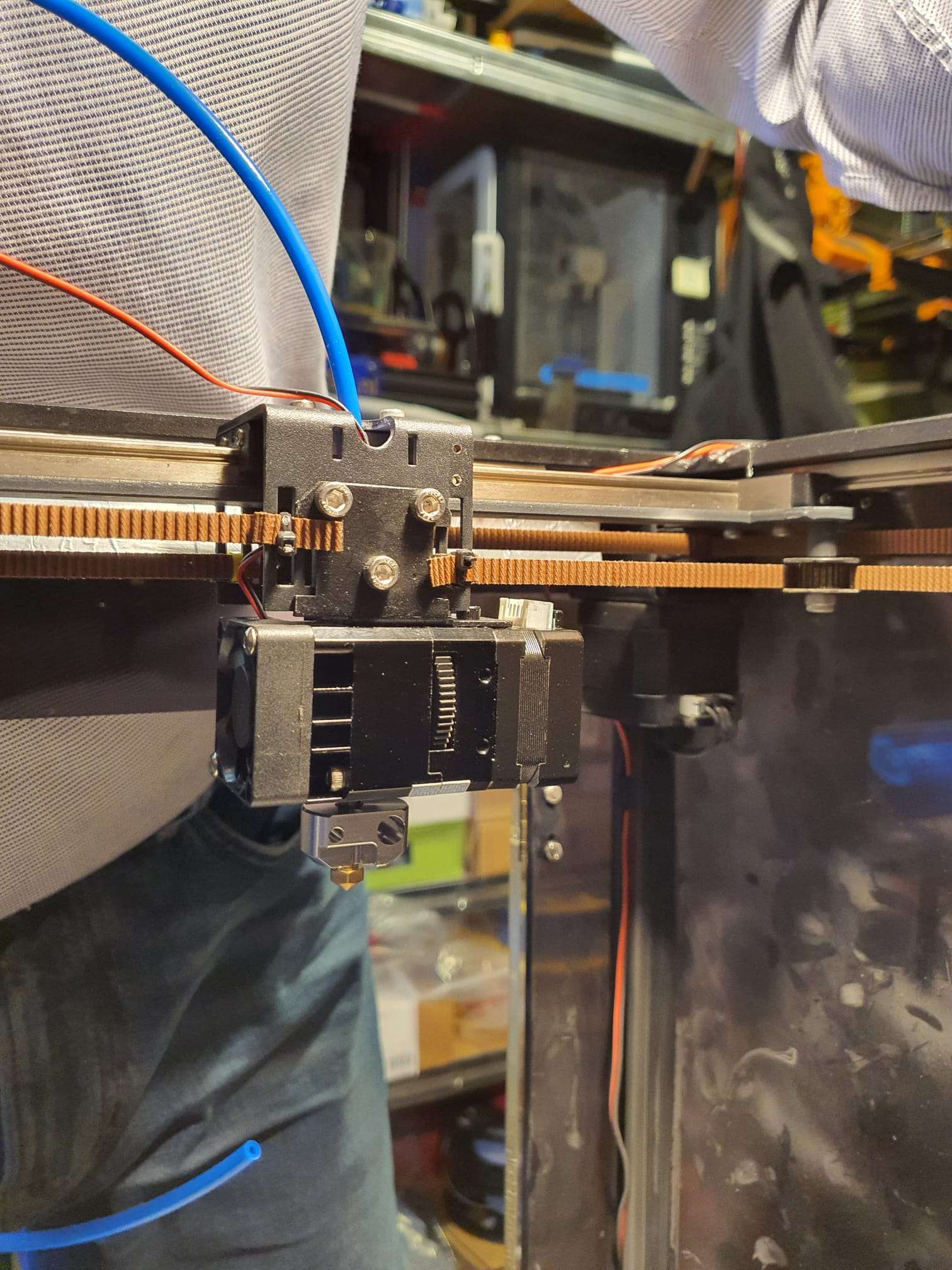

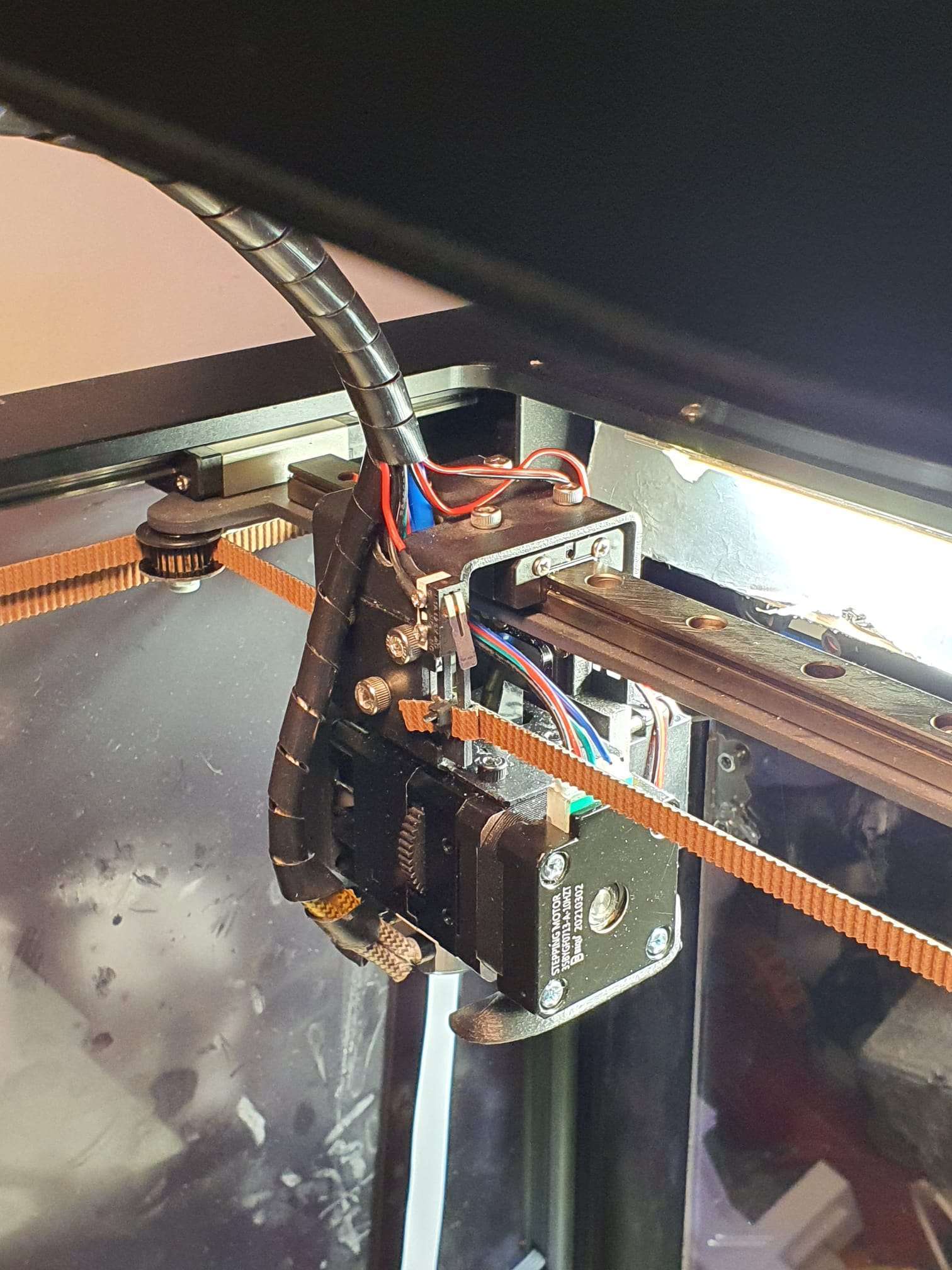

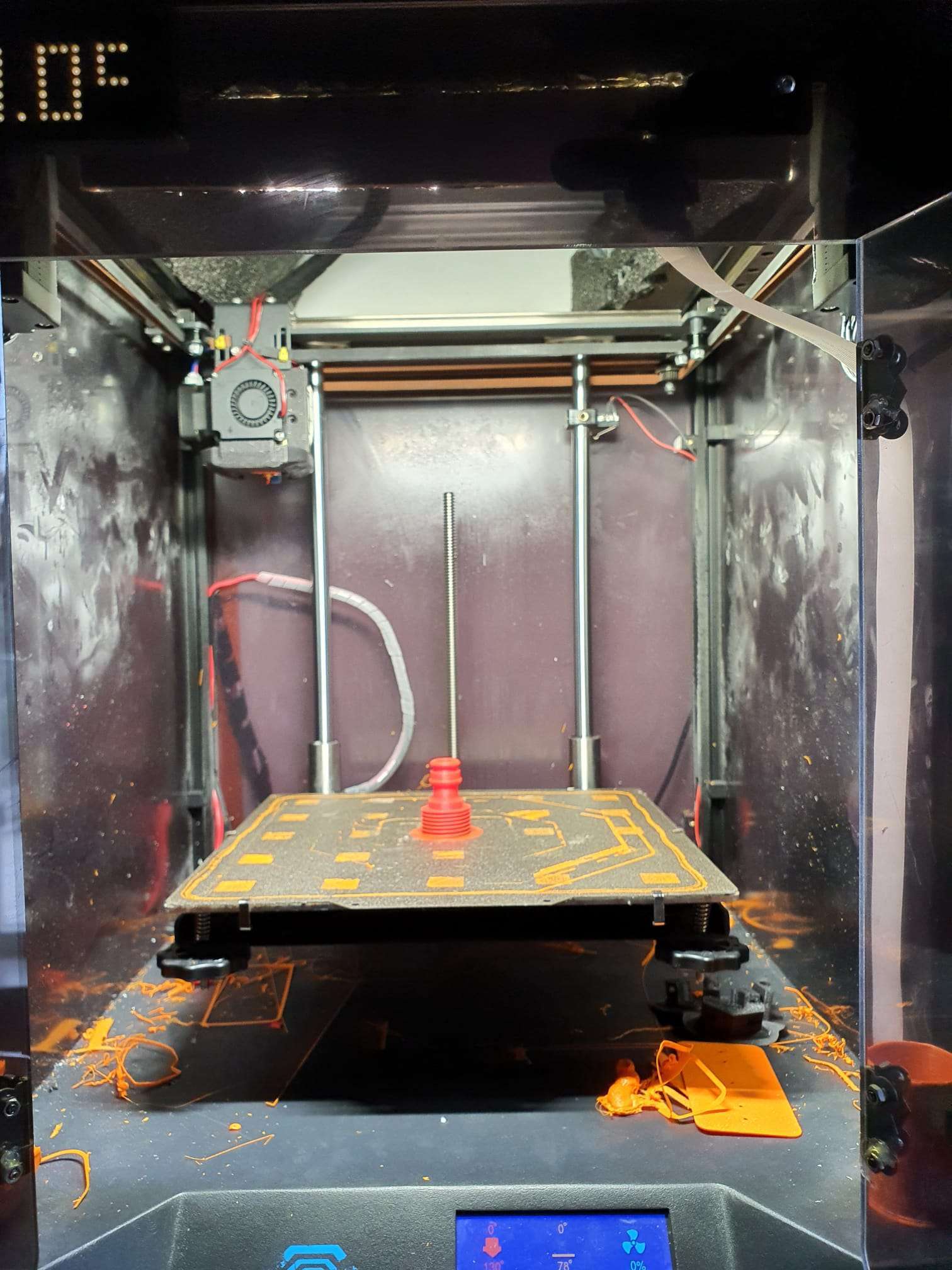

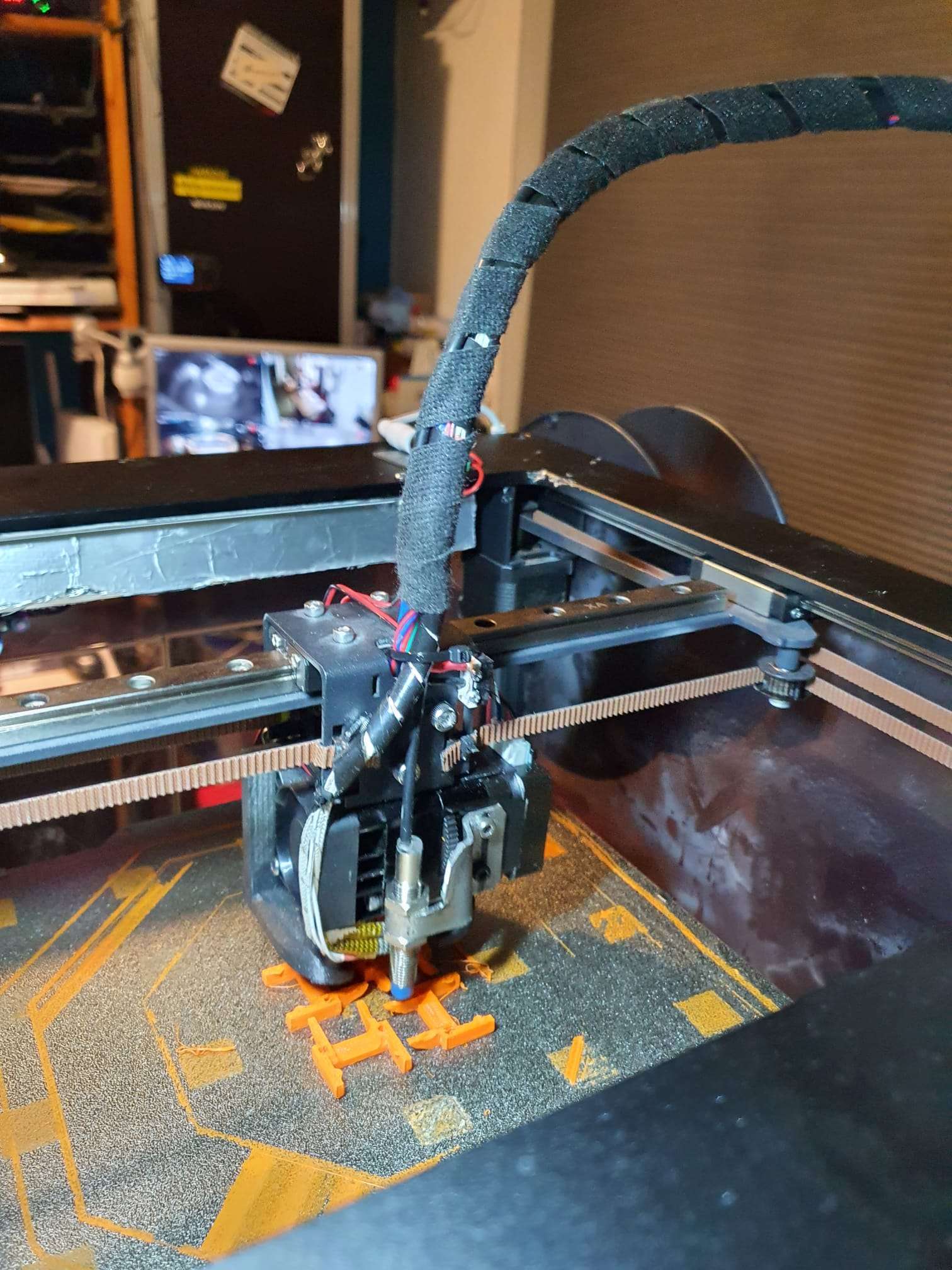

The first printer I chose to mount this extruder is my TT Saphire pro.

I own this printer for a couple of years, and it behaves quite well. But the original bowden setup is not my preferred setup, and the BIQUH2 seems very promising.

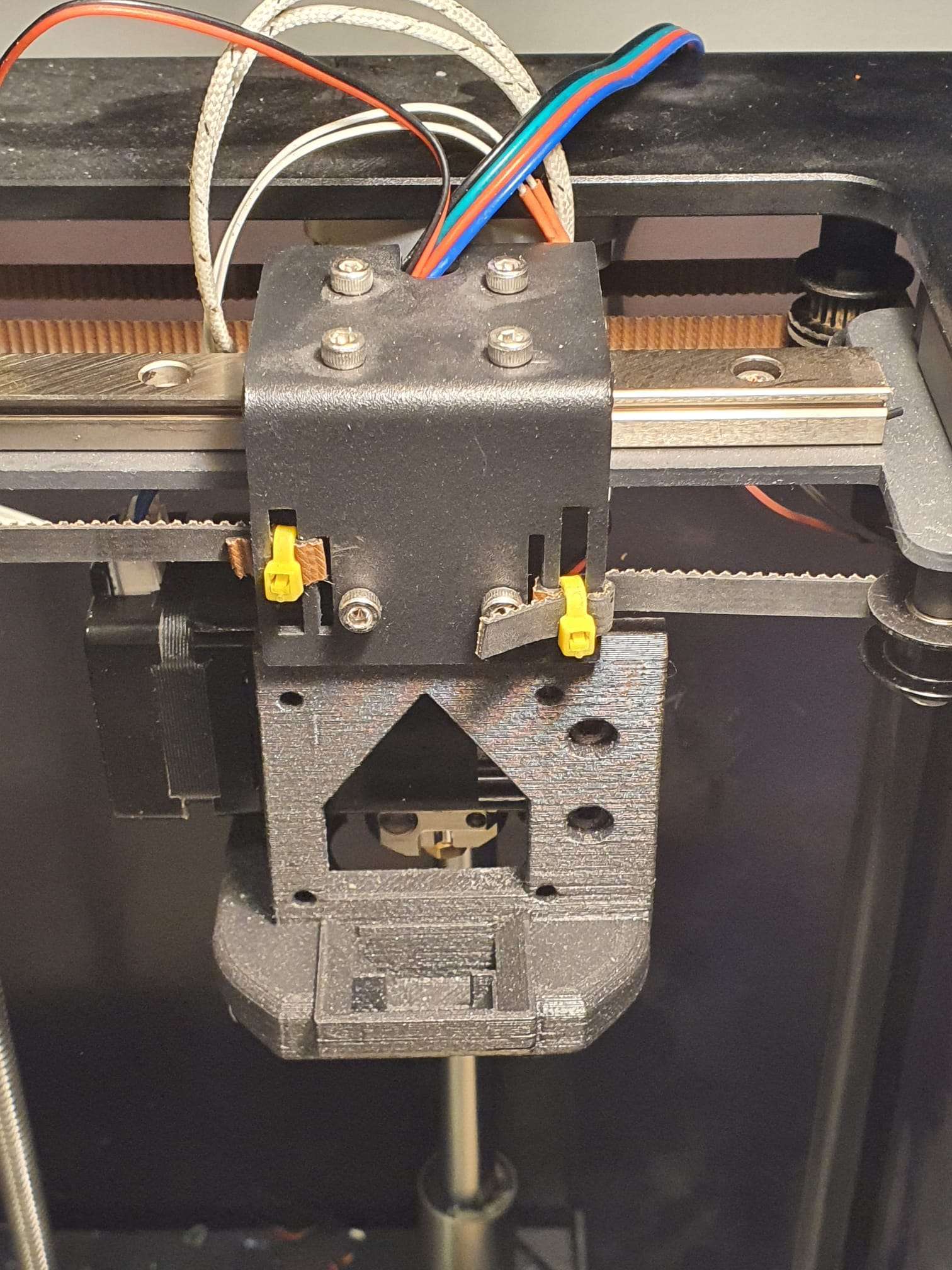

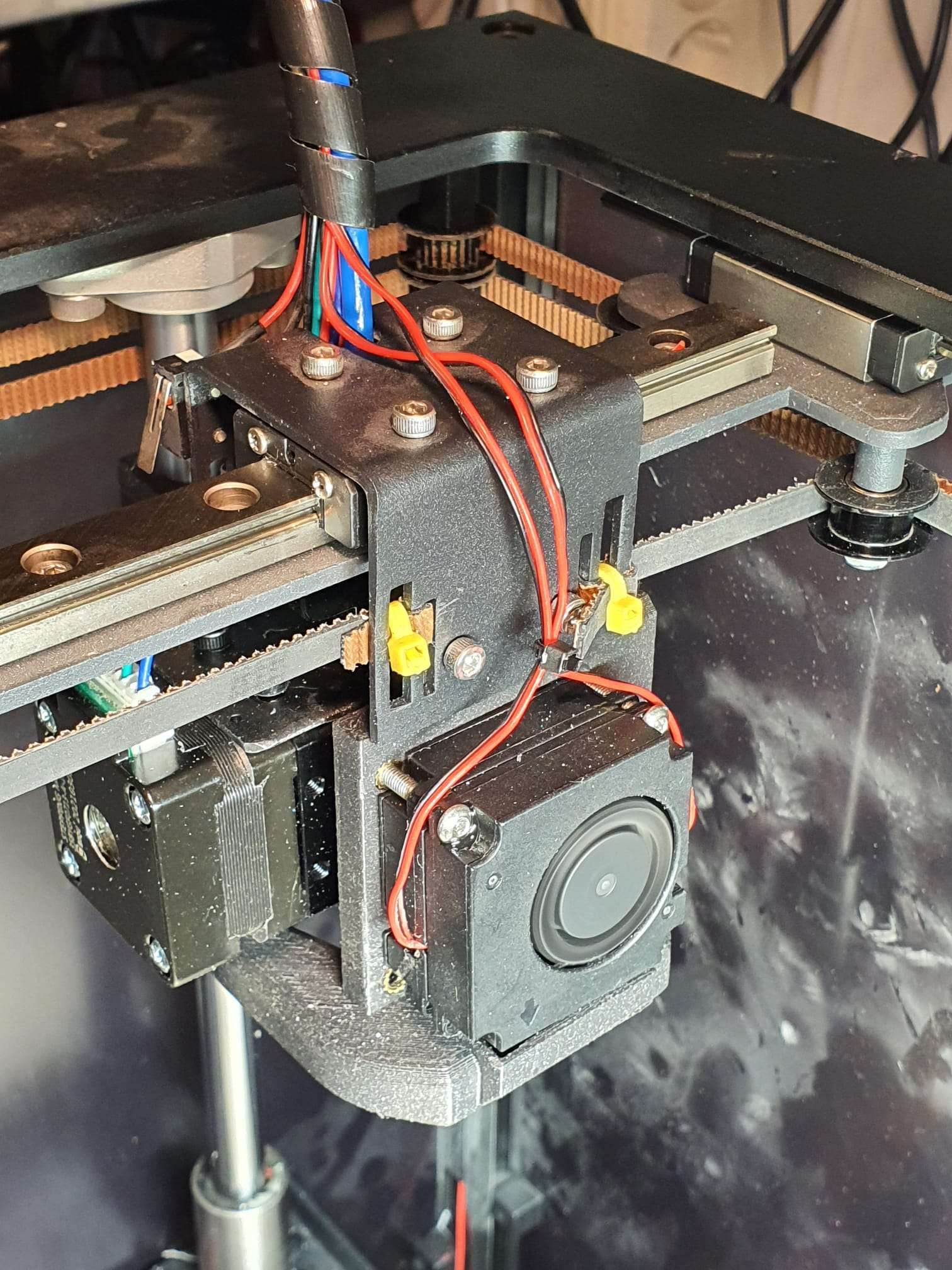

On the net, I found a 3d printable bracket with a seperate mount to re-use the 2 small 40mm side tool fans again as tool fans.

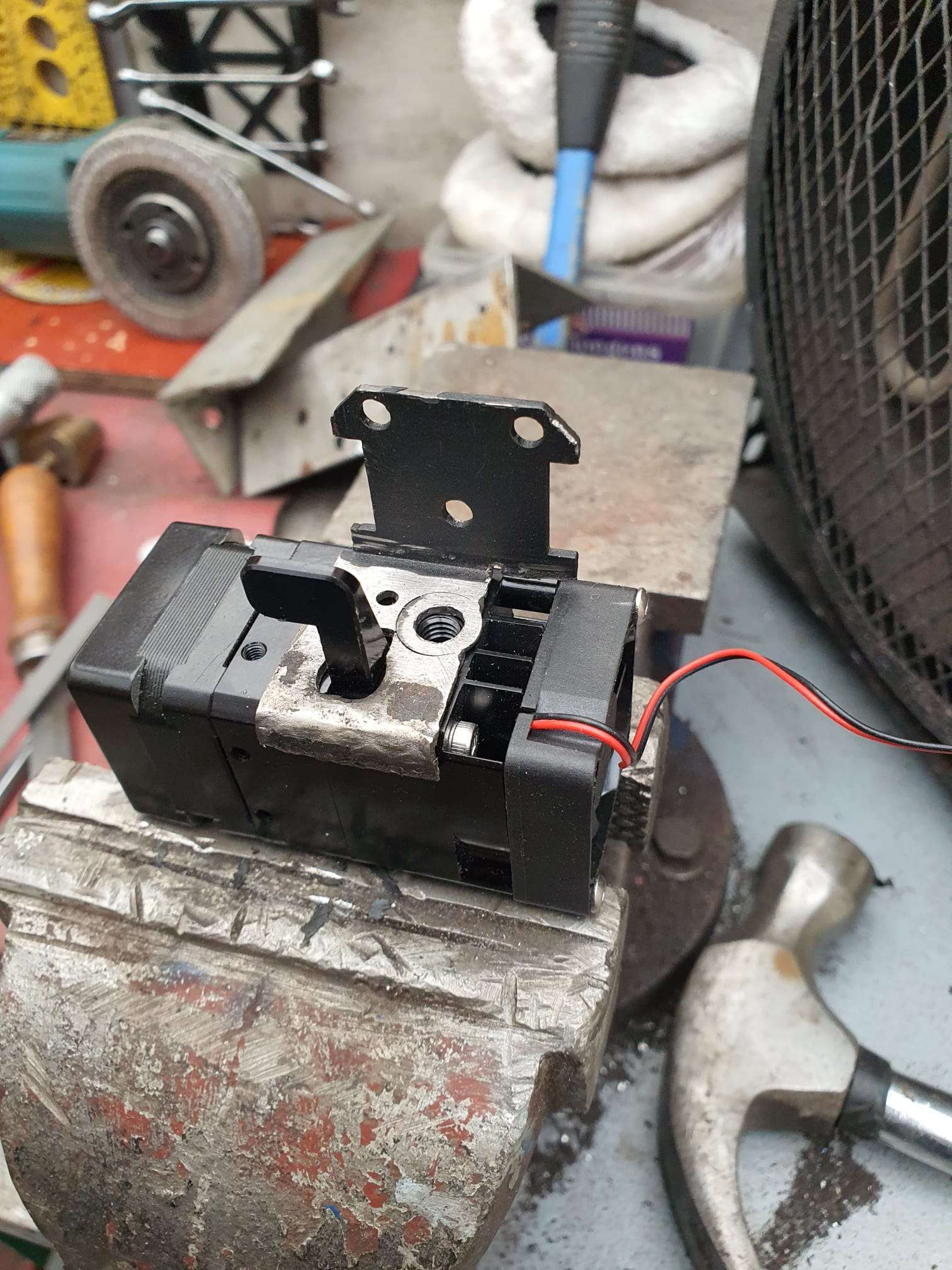

I ditched the 3d printed mount for the extruder and made me e steel one, from the old hotend mount. That is what the pictures in this article will show.

The 3d printed toolfan mount is a bit modded because I have reversed the entire setup, so I will keep within the original specs of 235x235x200 mm printeble size.

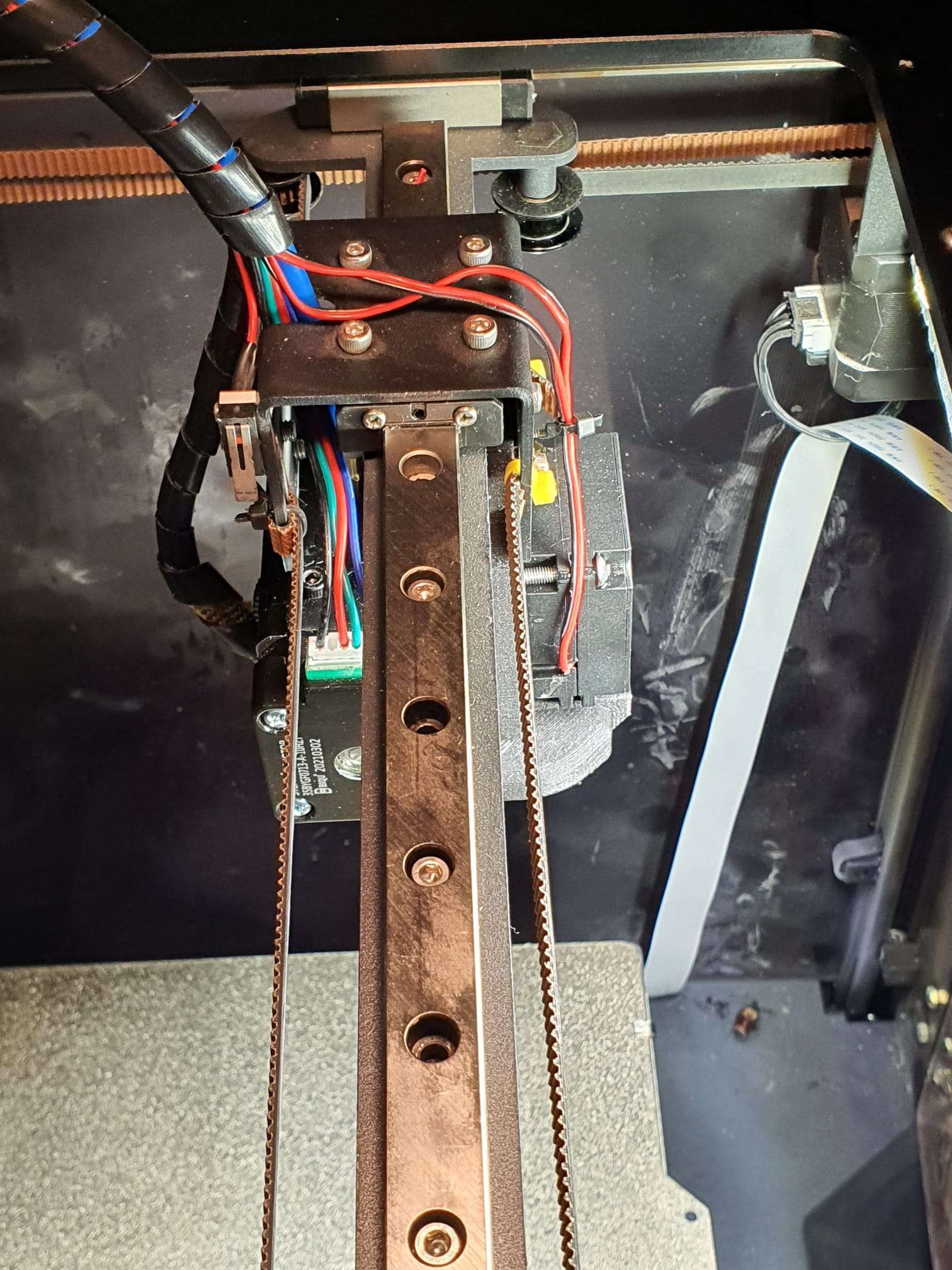

For the rest, please see the pictures. I re-used some of the old steel hotend mount, primarily the connecting plate with the XY carriage and the cornered horizontal plate.

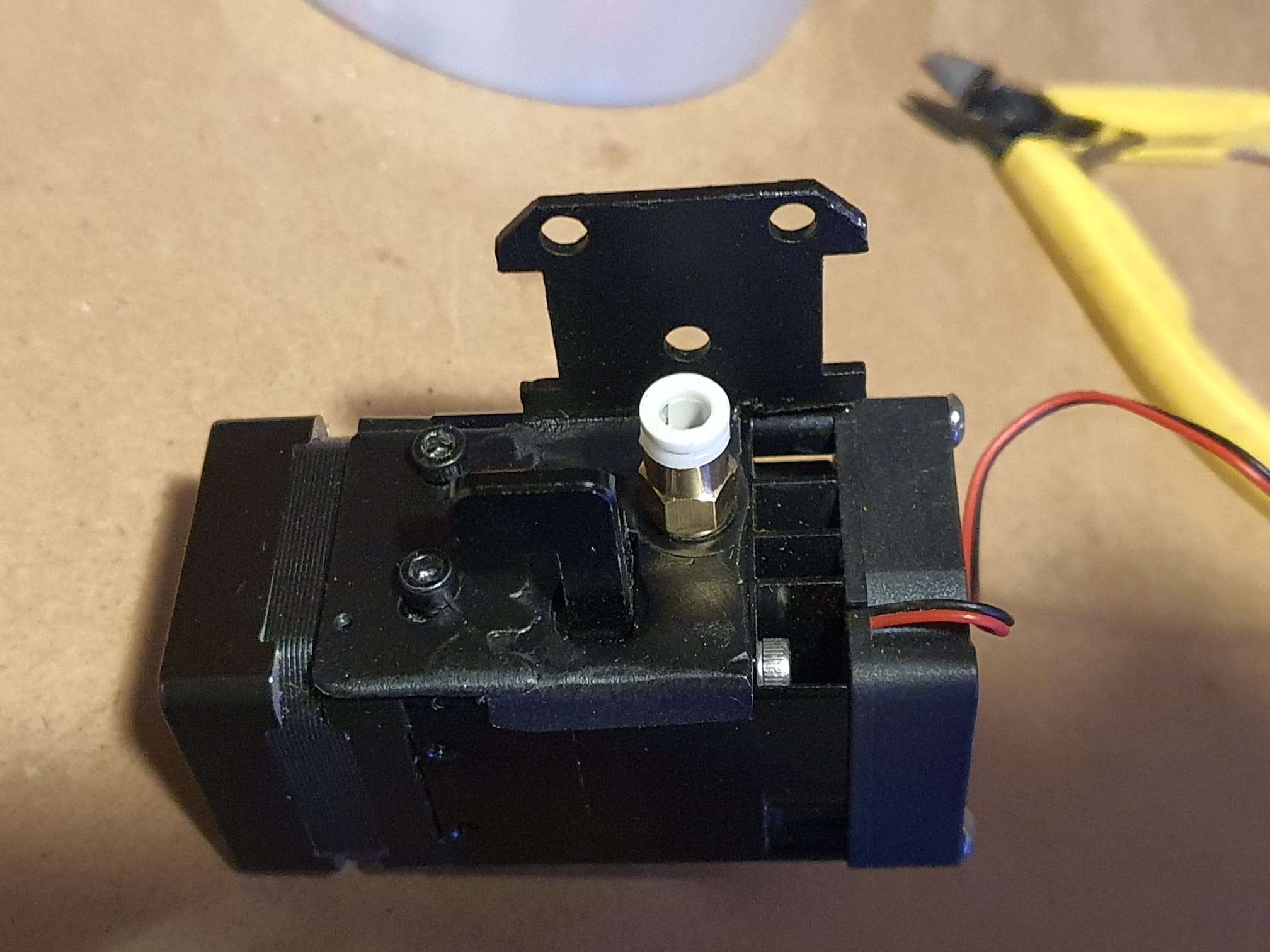

In the old big bowden tube hole I welded a 6mm inner- and 12mm outer dia ring in.

And I extended the horizontal base with a little piece of plate to use the 2 pieces 3mm threaded holes of the extruder’s upper side to bolt it all together.

The filament input of the extruder has a screw-in nut with a 4mm clamp for the ingoing 4mm tube, and this is the other mounting bolt to hold the extruder to the mount.